About the Company

The main activities include the modernization of turbine sets, especially their mechanical and hydromechanical control systems, including modifications of the existing control systems on the blocks of world-famous manufacturers such as Siemens, GE, LMZ, ALSTOM, MHI, Franco Tossi, KWU and ŠKODA. Also the production of new hydromechanical control systems, complete equipment for sugar cane processing (mills) and equipment for the separation of the liquid component of plant biomass.

Products and services

- Feasibility study

- Expertises

- Design and construction works

- Project documentation

- Production, tests at manufacturing plant

- Assembly, test, putting into operation at end user

- Warranty and also post warranty service

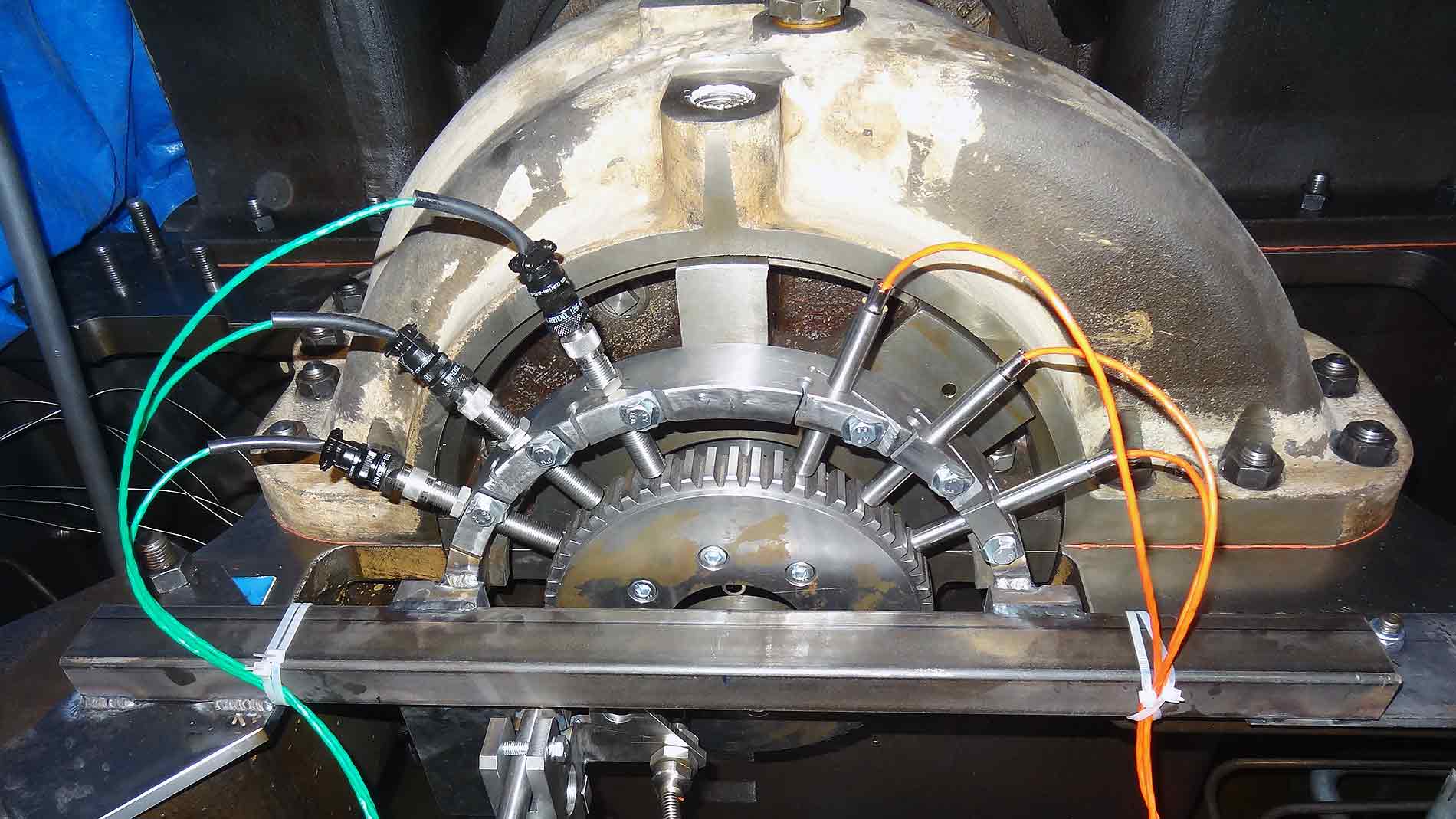

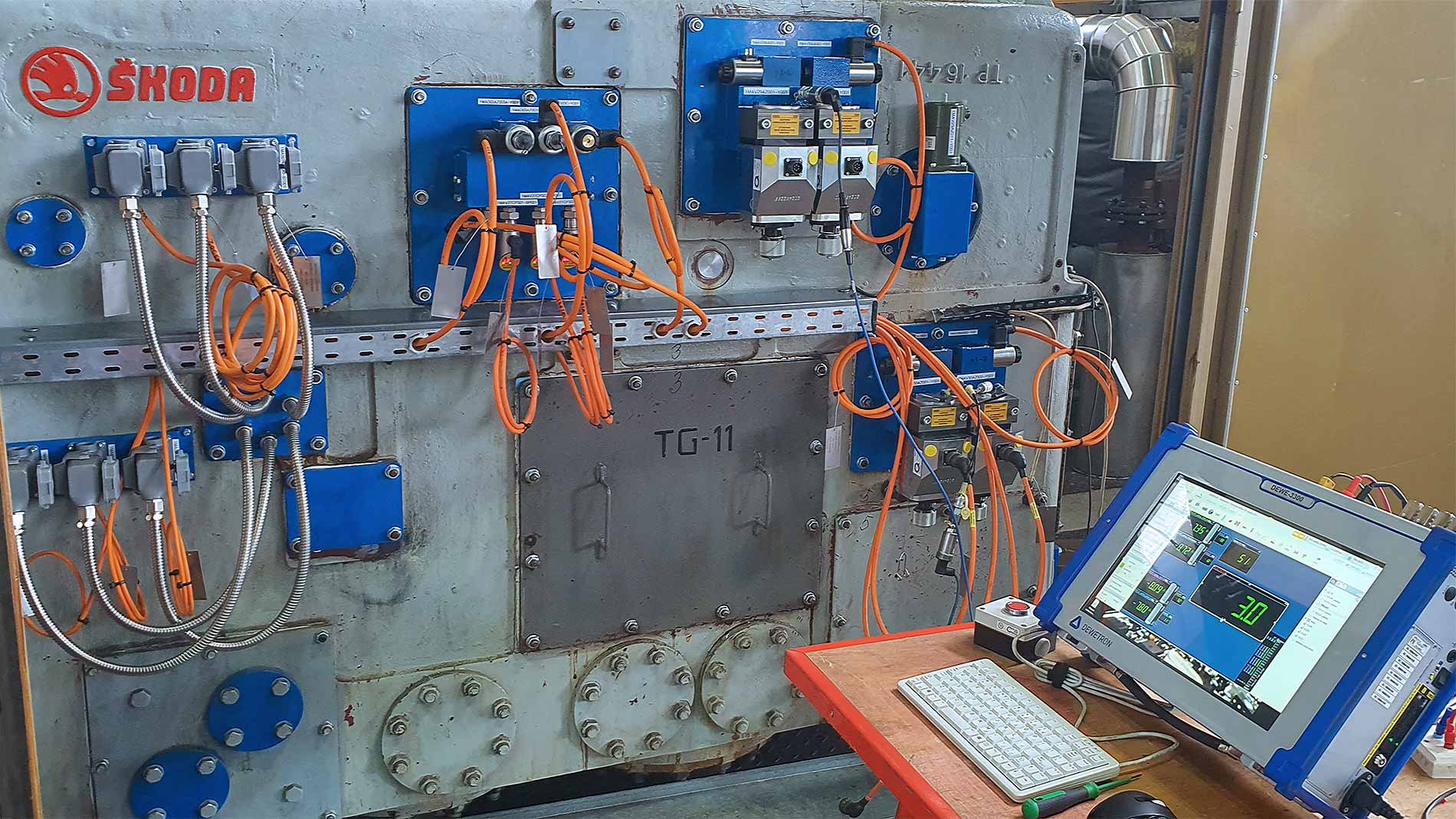

Modernization of the original regulation system for electronic control with direct control of valve actuators by electrohydraulic converters or servo valves. Application of modern electronic turbine speedprotection with a choice of two channels out of three. Production and installation of three channel Trip block with SIL 3 certification.

Installation on turbines with an output of up to 650 MW from all renowned world manufacturers (BBC, SIEMENS, LMZ, ALSTOM, MHI, FRANCO TOSSI, KWU, TOSHIBA, ŠKODA).

- Calculation of optimal parameters and device dimensions

- Installation of aggregate of high-pressure oil source

- Installation of new valve servo drives of the turbine

- Adjustment and putting into operation

- Measurement of static and dynamic properties of control systems, switch-off tests of turbo sets

- 4-roller mill (up to 45“ × 90“)

- 6-roller mill (up to 60“ × 90“)

- Separation of wood substance (e.g. Oil palm trees)

- Separation of industrially grown plants

- Separation of grass substance

- Separation of specific parts of municipal waste

- Feasibility study

- Expertises

- Design and construction works

- Project documentation

- Production, tests at manufacturing plant

- Assembly, test, putting into operation at end user

- Warranty and also post warranty service

Modernization of the original regulation system for electronic control with direct control of valve actuators by electrohydraulic converters or servo valves. Application of modern electronic turbine speedprotection with a choice of two channels out of three. Production and installation of three channel Trip block with SIL 3 certification. Installation on turbines with an output of up to 650 MW from all renowned world manufacturers (BBC, SIEMENS, LMZ, ALSTOM, MHI, FRANCO TOSSI, KWU, TOSHIBA, ŠKODA).

- Calculation of optimal parameters and device dimensions

- Installation of aggregate of high-pressure oil source

- Installation of new valve servo drives of the turbine

- Adjustment and putting into operation

- Measurement of static and dynamic properties of control systems, switch-off tests of turbo sets

- 4-roller mill (up to 45“ × 90“)

- 6-roller mill (up to 60“ × 90“)

- Separation of wood substance (e.g. Oil palm trees)

- Separation of industrially grown plants

- Separation of grass substance

- Separation of specific parts of municipal waste

Certification

Since 2007, we have implemented a quality management system in accordance with ISO 9001: 2015 and an environmental management system in accordance with ISO 14001: 2015 to ensure the top quality of our supplies and services.

Contacts

Address

Invelt Industry International, a.s.

Guldenerova 908/45

326 00 Plzeň

ID: 26360918

File number: B 1065 kept at the Register Court in Pilsen

Phones:

Secretary: +420 377 222 334, +420 731 128 833

- Fax: +420 377 222 335, +420 377 222 590

- GPS coordinates: 49.7401619, 13.3963219